Point Source Capture

Point Source Carbon Capture is the method of capturing CO2 straight from an emission source which can be one of, but not limited to:

🏭 Power plants (powered by coal or natural gas)

🧪 Chemical plants

⚗️ Fertilizer plants

🏗️ Cement plants

💧 Blue Hydrogen plants

When I started researching this category I didn't expect to find that: a) this is the oldest pathway (since the 70s!) from all the available ones which means that the technology has been proven at scale and used for decades and b) its relation with Hydrogen.

There's a lot to unpack, so let's get started.

How does Point Source Capture work?

There are three ways that point source capture can happen:

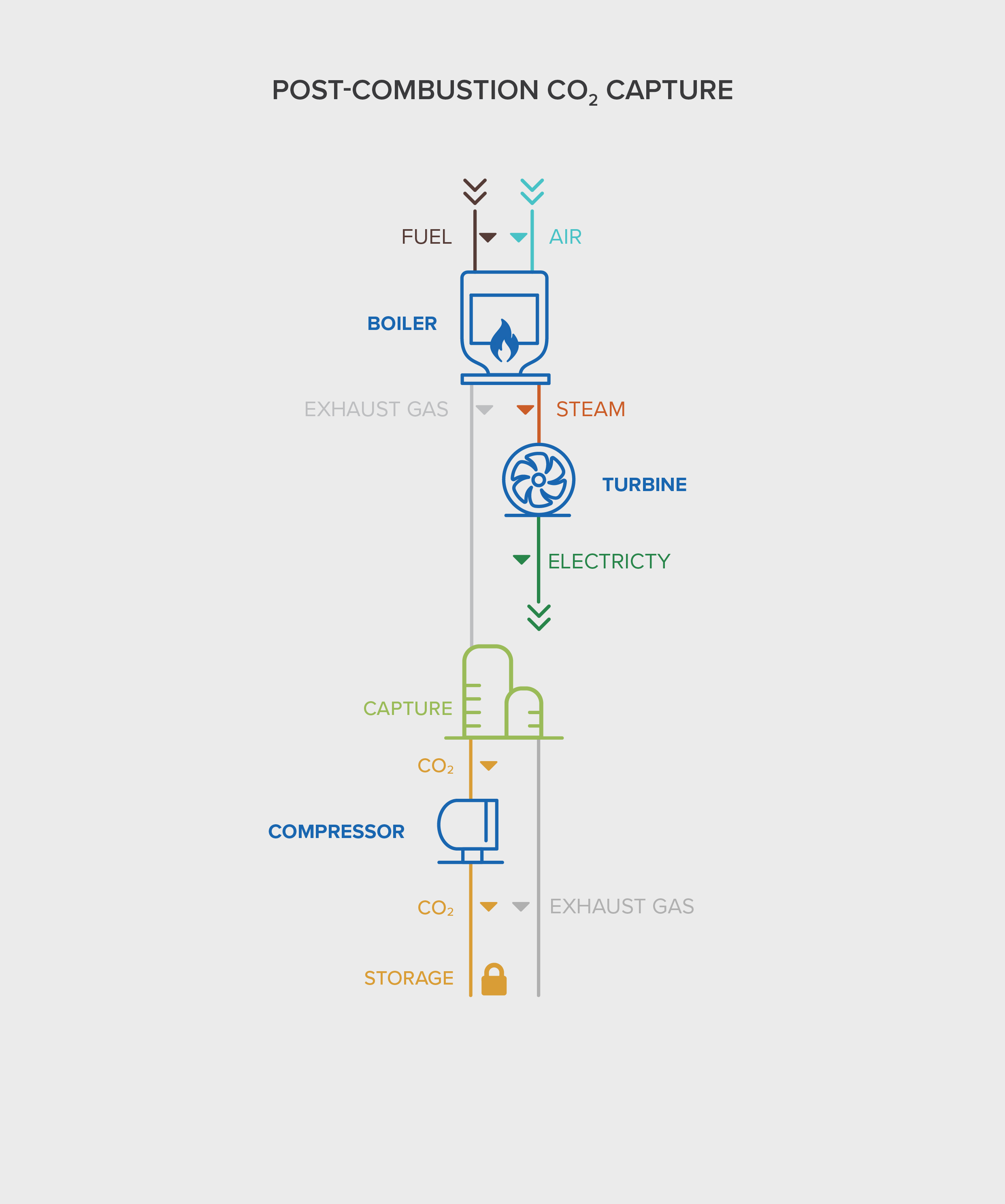

- Post-combustion, where CO2 is captured after the fuel combustion.

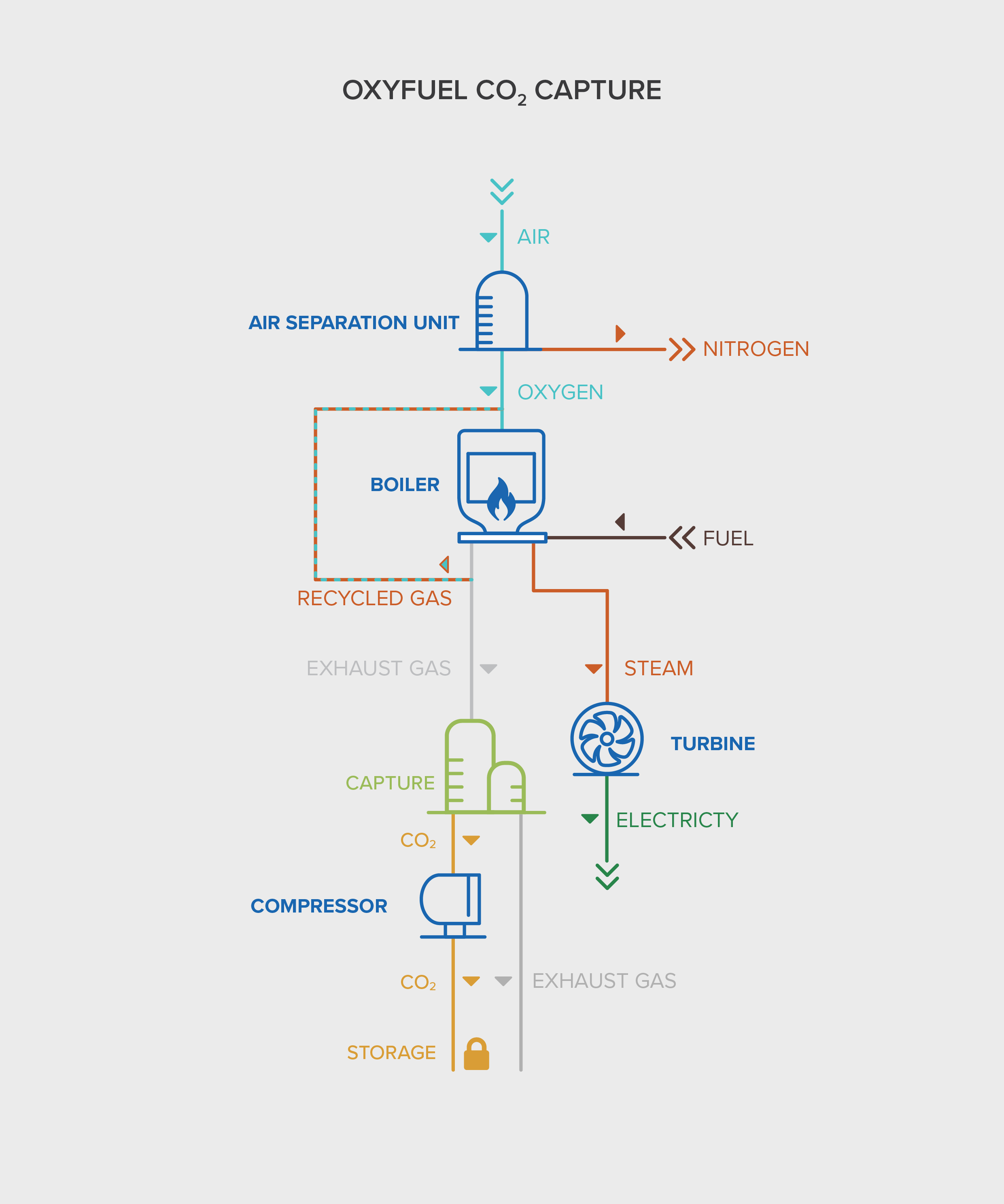

- Oxyfuel combustion, where the same as above happens only that the fuel is burned with pure oxygen so there is a "cleaner" emission to be captured.

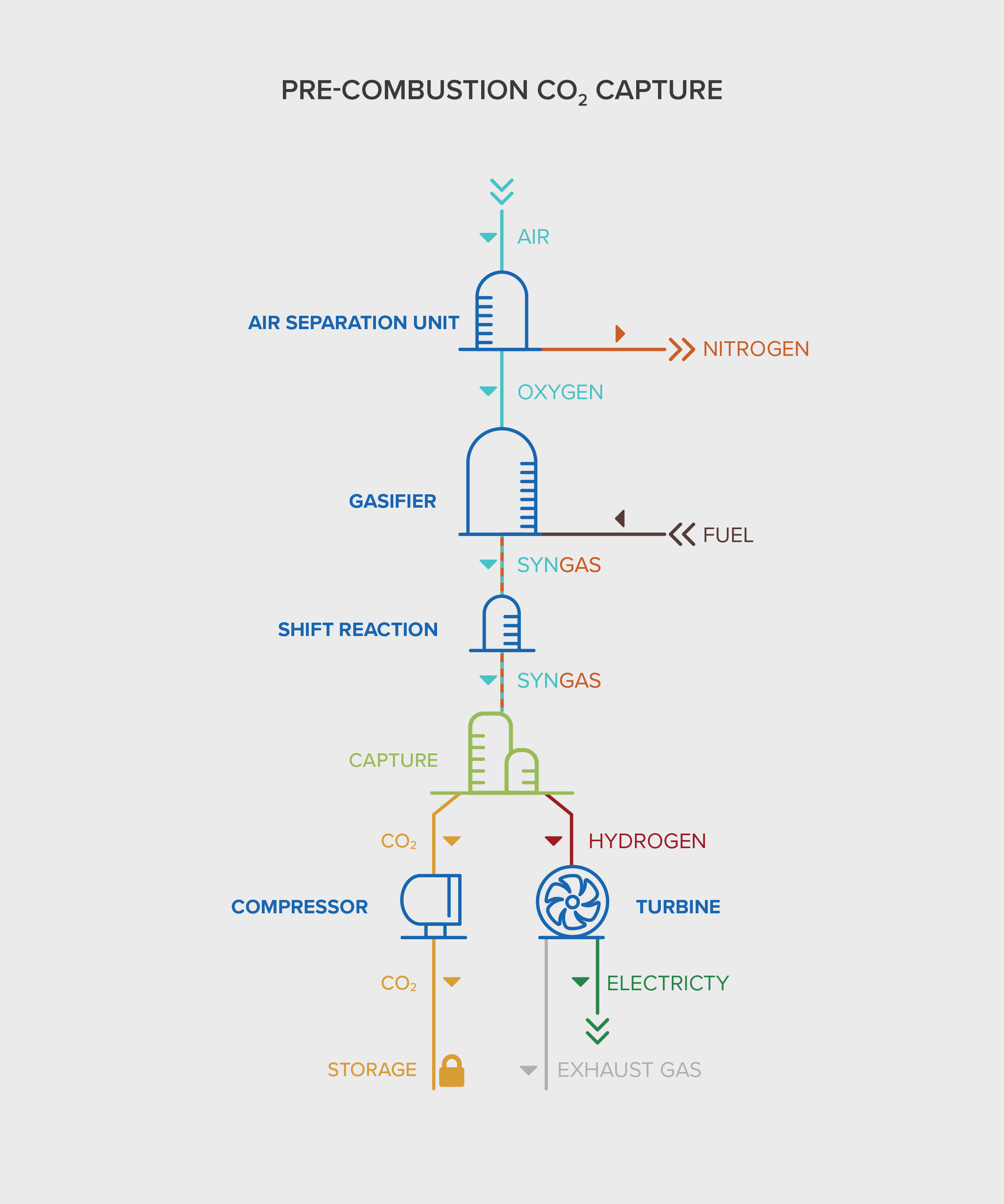

- Pre-combustion, where there is no combustion happening but the CO2 is removed physicochemically.

🔥 Post-combustion is, in simple terms, when you retrofit a carbon capture module on an existing plant and capture the CO2 emitted. This technology has been in use since the 1970s where it started being applied in natural gas processing plants like the one in Shute Creek where it has been capturing 7MtCO2 per year and using it in EOR nearby. Or in Sleipner, a Norwegian gas processing plant, which has permanently stored 1MtCO2 in a nearby geological formation as of 2018 saving the company $120,000/day in carbon tax money - this was also the first proven case of successful geological storage of CO2 where no leakage had happened in the 10 years after it storage.

🔥 Oxyfuel combustion is a similar method as above, in the sense of post-combustion capture, but with the difference that the fuel is burned with almost pure oxygen instead of atmospheric air. Atmospheric air has N2 and particular matter which can clog the filters and reduce their efficiency as well as their lifespan. If you go through the effort of separating these from O2 to purely burn only this, the combustion products are CO2 and H2O which are way easier to handle and sequester, which in turn means a lot of savings in money.

The challenge here is that more research needs to happen for a streamlined process for separating, transporting and feeding the O2 to the process so that the costs also drop. Pilot plants include power plants in Australia, Germany and Texas USA.

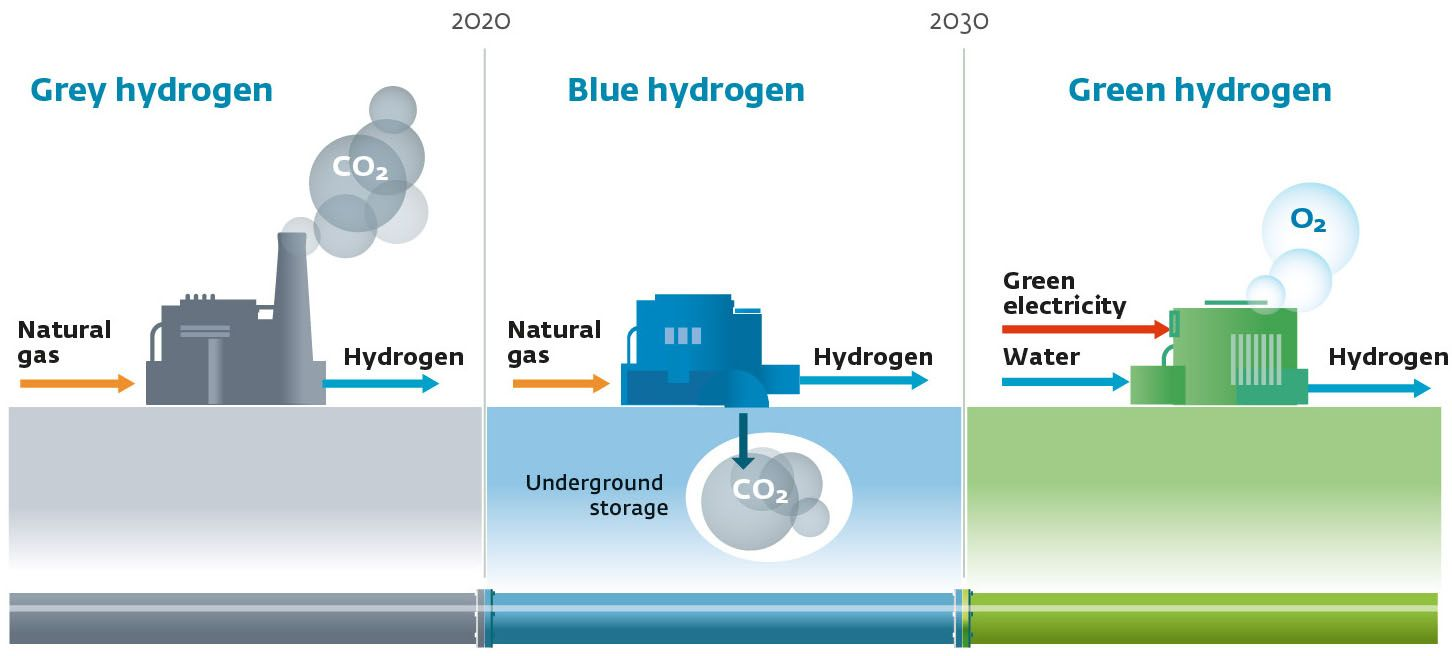

️⚗️ Lastly, pre-combustion is used when the fuel is converted into a gas under the pressure of steam which produces syngas, a synthetic gas that consists of CO, CO2 and H2 - yes, that Hydrogen which we all expect to become the alternative fuel of the future. This is where I got to learn about the ways that Hydrogen is produced and realized that pre-combustion is the same as Blue Hydrogen.

Some issues with this method is that you can't retrofit an existing power plant with carbon capture as it's a completely different process and in plants that are built with this way from scratch, if the capture process fails the entire plant (including the generation of fuel) has to shut down. This is obviously a nascent technology and the one of the oldest existing Blue Hydrogen plants is from the 2015 from Shell in Canada with a just 43% capture capacity but more are planned in the future that would capture up to 93%.

Where is all the attention?

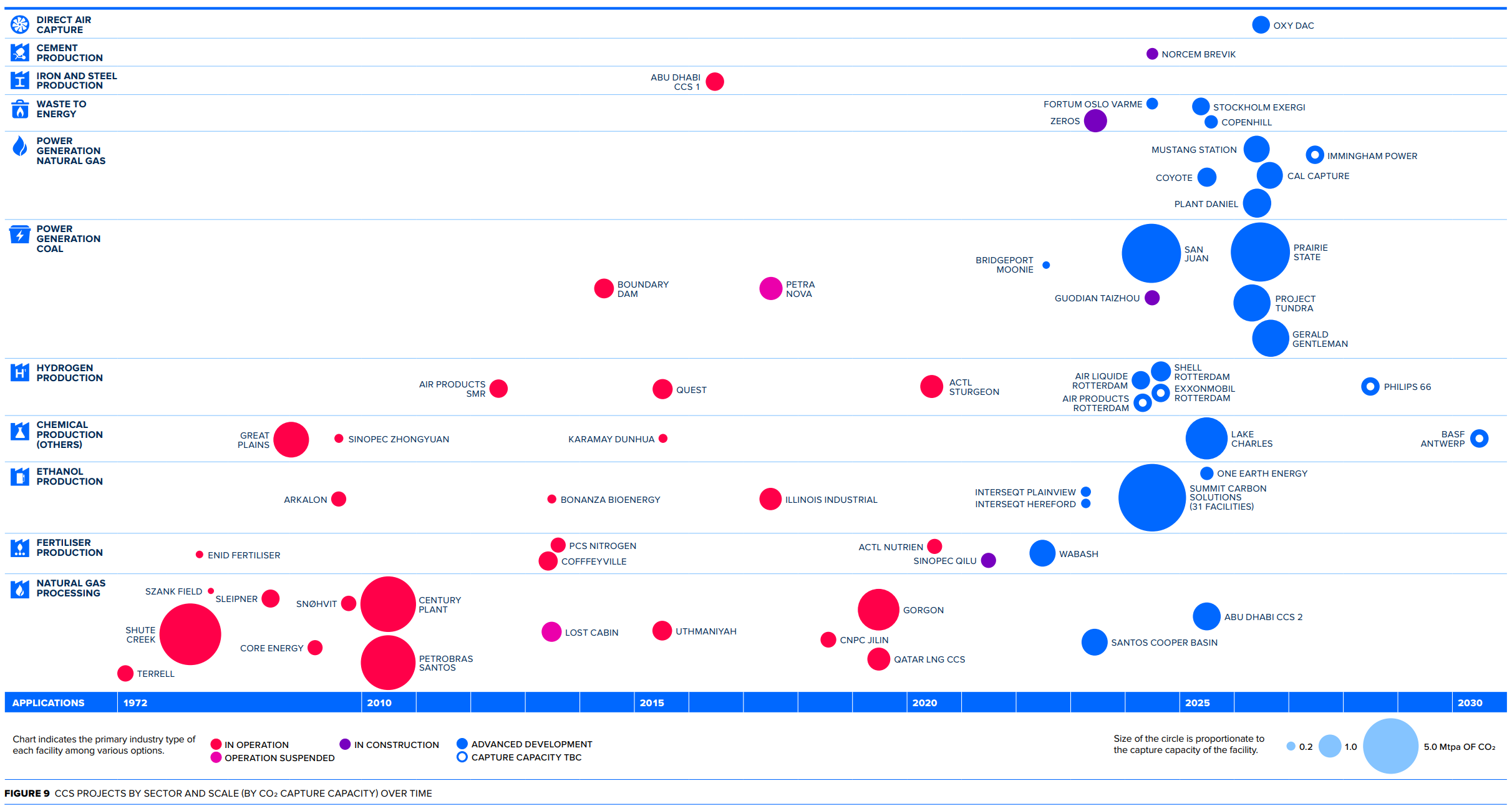

Since this is a relatively old technology which has already been applied in so many projects around the world (looking at the global status report of the CCS institute one can see that about 40MtCO2 per year are captured from plants that are currently operational with a 110Mt more coming soon from plants that are in development) I wondered why we are not reading more about this in the news instead of, say, technologies like Direct Air Capture and Biochar which capture CO2 in the smaller scale of thousands of tons.

Doing some research on the web I came upon two conclusions:

- This technology is tightly tied with fossil fuels and, as such, it's also going away together with them after 2030.

- It's too expensive to retrofit in old power plants.

Case 1: People don't want to talk about fossil fuels

If you look at the picture above, you will notice two things:

- The majority of projects is tied with fossil fuel technologies (natural gas and coal, specifically). Especially for natural gas processing, it seems to have worked quite well with only one project having stopped operations.

- There are no more projects planned for beyond the middle of this decade. This is in agreement to the global decarbonization plans which are going to become more aggressive from 2030 on so, thinking of the long lead time to create such projects (decade of planning and building, if not more), these 2025-2026 projects are the last ones that got on the train before the policy and carbon tax clamp got to them.

Case 2: It's too expensive to retrofit old plants

The above apply to new plants, but what about existing plants? Why can't we go on and retrofit carbon capture on existing coal and natural gas plants?

The answer is cost. Most coal plants have a life expectancy of about 46 years and the cost of retrofitting carbon capture on an energy plant of 500MWe is around half a billion $ (whereas building a new one with capture capacity is more expensive at 1.7B$). Also, capturing carbon reduces the efficiency of a plant, in this case from 33.6% to 24.7% (efficiency is the ratio of how much energy the plant generates divided by the heat it consumes) with 37% being the standard for a coal plant. That is a significant cost and efficiency hit, so unless the carbon tax is very high and there are no energy alternatives available, an organization would have to think hard before retrofitting an existing plant that is past its halfway mark.

What about Blue Hydrogen?

By now it's probably understood why Point Source capture on fossil fuel plants is not getting any attention and is going to go away, but what about the use case of Blue Hydrogen production?

As a reminder, Blue Hydrogen is the technology of Hydrogen production by way of steam reforming methane - a fancy way of saying that natural gas is turned into a gas by being steamed with water. The result of this process is syngas, which consists of H2, CO and CO2. Without even burning the fuel, we can capture the CO2 and produce H2.

This is, obviously, a process that is not the greenest one because:

- We don't have a 100% capture efficiency, though it's pretty close with 90-95%

- Methane is also emitted which is not captured

However, there are currently no reliable or cheap alternatives to produce Hydrogen. The only other way is Green Hydrogen which is based on electrolyzing water in order to split it into H2 and O2, by using renewable power. Its defining characteristic is also its achilles heel - there is not enough or cheap renewable energy for that and if you build dedicated power infrastructure like a dedicated photovoltaic park, you run into other problems of land size and cost.

Looking at calculations from four independent organizations (CSIRO, IEA, IRENA, Hydrogen Council) the cost of producing Blue Hydrogen floats at around 2$/kWh whereas for Green Hydrogen it's about double that at 4$/kWh(download the PDF of the whole Hydrogen report here).

The good news are Green Hydrogen costs are expected to decrease together with electrolyzer costs and as more renewables enter the grid. The bad news are that if we are serious about using Green Hydrogen for so many of our current fossil fuel uses, we would need 18 times the current global solar power or 6 times the existing wind capacity.

Also, considering that governments and markets are not going to wait for Green Hydrogen to become economically feasible overnight before building infrastructure to transfer it and use it (just think how long it will take until we start seeing mainstream adoption of H2 cars, if it ever happens), cancelling every Blue Hydrogen product in the name of decarbonization is not a smart move - there's just so much that needs to be derisked at scale before we get to use Green Hydrogen.

I also wonder would the environmental impact be if, in a non-ironic way, a green hydrogen plant used energy that is produced from a power plant that burns fossil fuels but captures about 90% of its emissions 🤯.

Did you enjoy this article? If yes, then please share this with your friends on your social media and, if you haven't, please subscribe to receive more articles like this.